Certification

021-660 32575

DOSH

Personal Protective Equipment (PPE), hearing tests, elevators/escalators/lifts manufactured or exported to Malaysia for use , Sandblasting, cranes/windlasses, oil pipeline design, non-combustion pressure vessels, steam boilers and all other pressure-bearing equipment must be authorized by a third-party inspection agency as the “inspection agency”of te Ministry of Occupational Safety and Health (DOSH) Certification of design, manufacturing, and inspection processes. Domestic manufacturers can design according to relevant standards of developed countries such as ASME code or BSI code (must be signed and approved by an overseas authorized inspection agency). At present, the most common method is to convert design drawings, calculations, etc. into ASME standard documents, which can simplify the workload of related applications for certification.

The following is a detailed introduction to the DOSH certification details of various products

1. Personal protective equipment

According to the 1994 Occupational Safety and Health Regulations, the following seven types of personal protective equipment must have DOSH certification:

1) Respiratory Protection (JKKP HIE/12/2/1) 2 )

2) Hearing Protection (JKKP HIE/12/2/2)

3) Eye Protection (JKKP HIE/12/2/3)

4) Hand Protection (JKKP HIE/12/2/4)

5) Foot Protection (JKKP HIE /12/2/5)

6) Body Protection (JKKP HIE/12/2/6)

7) Head Protection (JKKP HIE/12/2/7)

certificate is valid for five years.

2. The hearing test is

in accordance with the Malaysian 1989 Factory and Machinery Exposure Noise Regulations, and employees are prohibited from working in an environment where the noise level exceeds 85Db or the daily noise dose exceeds 0.5.

3. Elevators/escalators/lifts

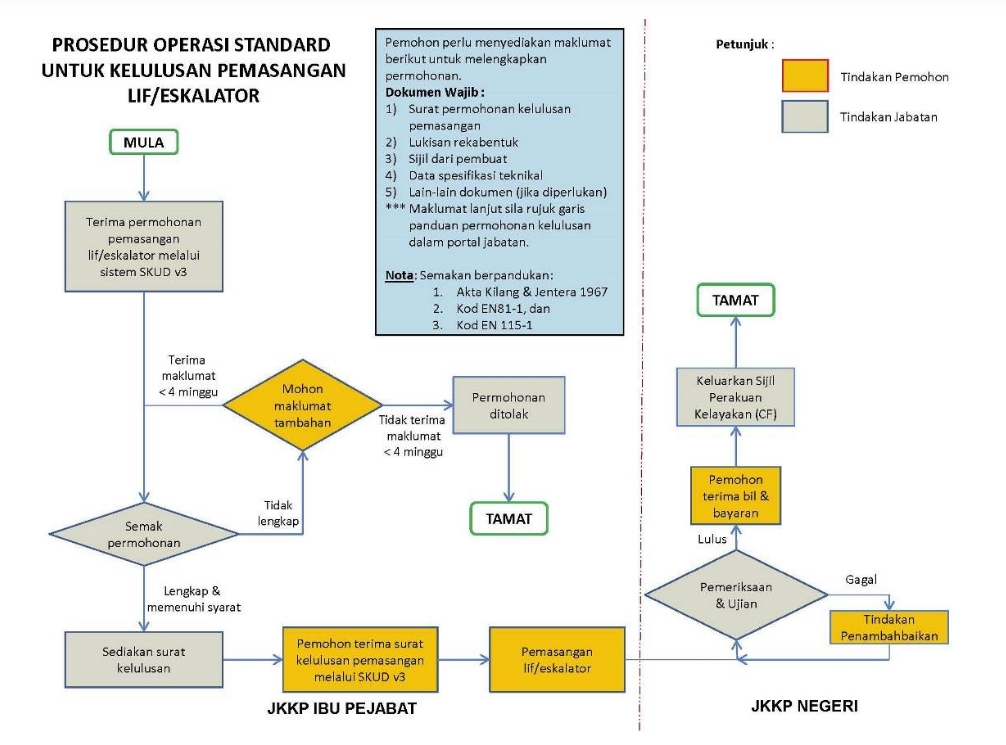

According to the Electricity Regulations of 1970, the design and manufacture of elevators, escalators, and elevators need to be approved. The application process is as follows:

4. Sandblasting

According to Article 5 of the 1989 Factory and Machinery (Mineral Dust) Regulations, sandblasting must be approved by an authorized inspector before it can be used.

5. Design approval for hoisting equipment of traction machine

Lifting equipment includes electric power, diesel engine, pneumatic or other various drives. All non-manual traction equipment used for lifting and traction must have an installation permit, and the relevant design must be approved by the OSHA department.

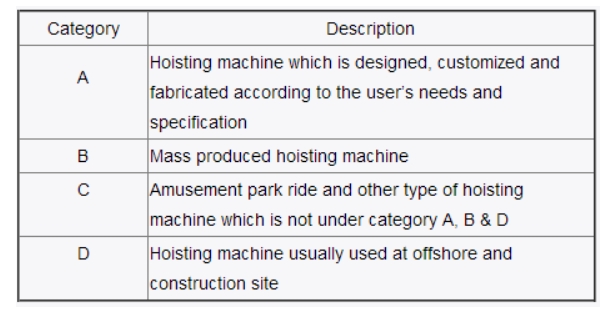

Lifting equipment is mainly divided into the following four types:

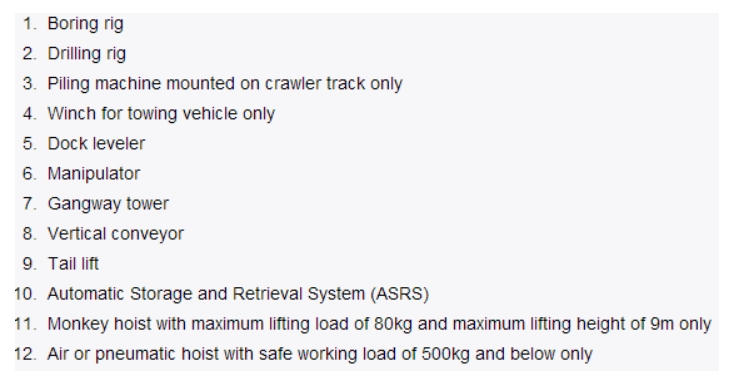

The following 12 equipment does not require DOSH certification.

All lifting equipment must be installed by a capable installation company, and the installation company must be registered with OSHA.

Mobile cranes, crawler cranes, truck-mounted cranes, injection pile drivers, screw cranes and mobile lifting platforms must obtain DOSH certification separately for each model.

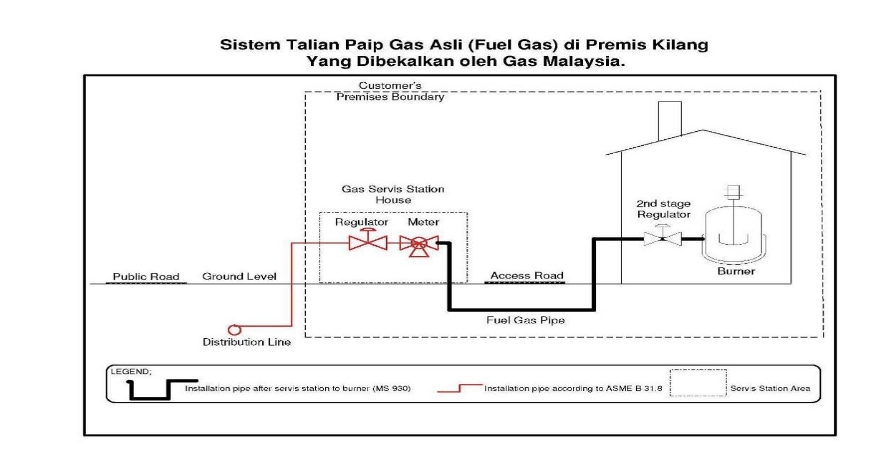

6. Pipeline Design

In 1992, the Ministry of Domestic Trade and Consumer Affairs of Malaysia was authorized to manage the Petroleum Safety Management Act. The 1984 Act stipulates that oil safety management includes the safety of petroleum transportation, storage, processing and the use of petroleum equipment. In order to ensure the smooth implementation of the law, DOSH is entrusted and authorized by the Ministry of Health to manage its implementation.

The guide is mainly to guide the relevant application process, mainly the installation permit of petroleum pipelines, and the operation permit of pipelines and large-scale storage equipment. Such applications are mainly divided into the following four categories:

1) PTI petroleum pipeline installation permit

2) PTO petroleum pipeline operation permit

3) oil and gas storage equipment installation permit

4) petroleum equipment approval

7. Non-combustion use pressure vessel

DOSH Certification scope Pressure vessels with design pressure × inner diameter less than and greater than 3000psi-inch need to apply for Malaysia DOSH certification separately .

The following types of non-combustion pressure vessels require design approval:

a. Gas tank

b. Autoclave

c. Liquefied petroleum gas storage tank

d. Heat exchanger

e. Pressure vessel

drawing format reference of petrochemical plant

8. Steam boiler and pressure vessel equipment The

following types of steam boilers must be registered with DOSH

1. Water pipe Boiler

2. Cupping boiler

3. Electric boiler

4. Waste heat boiler

DOSH certification process

1. Conduct design review (drawings and calculations) in accordance with DOSH approved construction codes (such as ASME Code Volume VIII-1)

2. Review related manufacturing Procedures and technical requirements, quality control plan of the manufacturer, etc., and establishment of inspection points

3. Verify or inspect incoming materials

4. Review welding procedures, process qualification records and welder qualification records

5. Review non-destructive inspection procedures and personnel qualification records

6. Random inspection during the manufacturing process, such as welding seam group inspection, welding seam back root removal inspection and dimensional inspection, etc.

7. Witness non-destructive flaw detection or review non-destructive flaw detection reports/records

8. Final appearance and dimensional inspection, including internal and external equipment Inspection

9. Review the heat treatment report (if applicable)

10. Witness the final pressure test

11. Review the inspection records and reports of the manufacturer.

12. Confirm the contents of the nameplate and the installation of the nameplate, and mark the nameplate with the item identification number.

13. Issue the DOSH certification inspection certificate